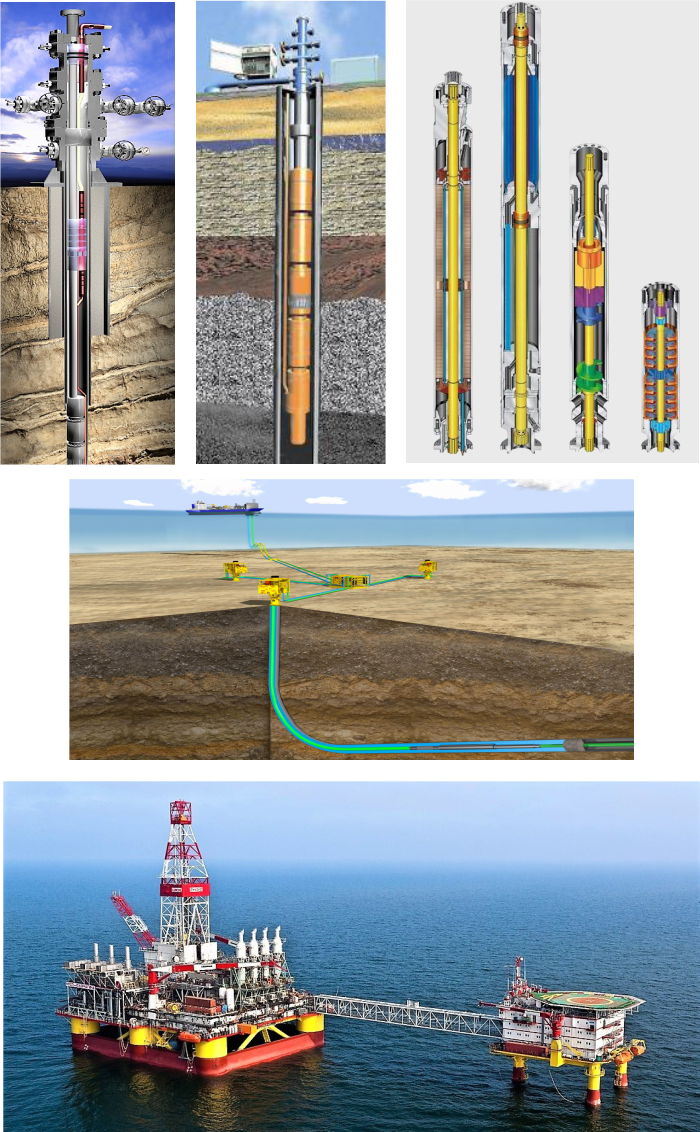

ESP systems

In the world, where many larger oil wells have declined in production, ESP systems are the best choice. Older gaslift systems which now have a high water cut would produce to lower pressure and produce higher recoverable oil if money were spent to re-equip them with ESP’s.

Electrical submersible pump (ESP) systems are a common artificial-lift method, providing flexibility over a range of sizes and output flow capacities. Electric submersible pumps are typically used in older reservoirs on wells with high water cuts (percentage of water to oil). ESP’s provide cost effective production by boosting fluid production from these less efficient, older reservoirs.

ESP completions are an alternative means of obtaining artificial lift in wells that have low bottom hole pressures. ESP completions are the most efficient choice for high volume capable wells.

ESP advantages:

- Due to these minimal surface requirements, ESP are applied in limited space areas such as offshore facilities if pulling costs are controlled;

- ESP are used in locations where gas is not available for a gas lift system;

- ESP’s are one of the higher volume methods of lift;

- ESP can create a higher drawdown on the formation and achieve more production;

- Casing size let pump high volumes. As waterflood volumes increase, it is common to pump several thousand barrels of fluid a day while trying to improve formation sweep efficiency;

- This system is easy to adapt to automation and can pump intermittently or continuously but continuous work is preferred for longer life;

- Relatively low investment for shallow wells.